Closed cycle spray dryer is a special equipment for drying organic solvent slurry. The unit uses nitrogen (or other inert gas) as the drying cycle gas, which prevents oxidation of the materials during the drying process and recovers organic solvents. The closed cycle spray dryer is generally used for drying the powder of slurry prepared by organic solvents such as ethanol, acetone, hexane, etc. The equipment is explosion-proof, and the drying process is safe and environmentally friendly.

Closed circuit circulating spray dryer, which is suitable for preventing oxidation during drying process, and requires high powder consistency after drying. Such as powders in industries such as pharmaceuticals, chemicals, food, and lithium battery materials. The average particle size of 10-100 μ m can be obtained by centrifugal spray. Of course, the entire drying process is completed under nitrogen protection, and organic solvents can be recovered simultaneously.

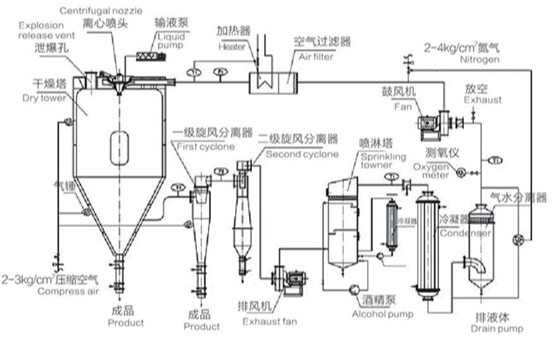

RDBLPW series closed circuit circulation spray dryer works in a closed environment. The drying medium is inert gas (generally N2), which is suitable for drying materials containing toxic gas or materials prone to oxidation during the drying process. The system uses inert gas as the circulating gas, which has a protective effect on dry materials. The circulating gas undergoes processes of moisture loading and dehumidification, and the medium can be reused. After being heated by the heater, nitrogen enters the drying tower, and the liquid material is transported to the centrifugal nozzle by the screw pump. The liquid is atomized into droplets by the high-speed circulating atomizer, and the heat and mass exchange process is completed in the drying tower. The powdered material after drying is discharged from the bottom of the tower. The evaporated organic solvent gas, under the negative pressure of the fan, condenses the dust trapped in the gas through the cyclone separator and spray tower dust removal, and the saturated organic solvent gas is condensed into liquid and discharged from the condenser. The non condensable gas medium is continuously heated and reused as a drying carrier in the system. The conventional conventional centrifugal spray drying achieves the purpose of moisture removal through continuous air supply and exhaust, which is also an obvious difference between explosion-proof closed centrifugal spray drying equipment and conventional centrifugal spray drying equipment; The drying medium in the drying system is N2, and the internal operation is under positive pressure to maintain a certain positive pressure value. If the internal pressure drops, the pressure transmitter will automatically control the N2 inlet to ensure system pressure balance.